In-The-Can Measurement of Thermal Burn-out damage

from regeneration

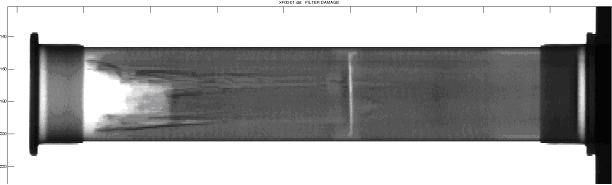

The photo below shows thermal damage in a diesel oxidation catalyst. This catalyst is comprised of two monoliths placed end to end. The x-ray image was taken through the can, i.e. through the metal tube assembly, which is part of the exhaust system. This image was made on the MDXi400 X-ray system and took approximately 10 seconds to make.

Extensive damage is clearly seen at the left end (inlet), and some damage extends through the length of the first monolith and into the top of the second monolith. The white vertical line in the center of the image is the gap between the two monoliths.

An interesting perspective can be seen by looking at this Flash Movie . This was made by using the batch file capability of the MDXi400, to take multiple images of the diesel oxidation catalyst, while progressively rotating the angle of the turntable. These images were stitched together to create the avi clip shown. You will see the damaged areas appear to rotate with the part rotation. The occasional 'flashes' inside the filter, occurs when the monolith channels are aligned with the beam allowing more x-rays through.

|